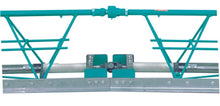

WSHE/MSHE Series Vibratory Truss Screed ideal for jobs ranging from small to large flat work pours, bridges and highways and many applications in between

Multiquip's vibratory truss screed exceeds contractor's expectations for leveling pavement and industrial floors. Its proven steel design has made it a favorite of concrete contractors for years.

- Eccentric shaft design produces 8,000 vibration cycle nodes per minute

- Ideal for jobs ranging from small to large flat work pours, bridges and highways and many applications in between

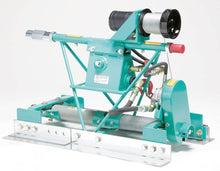

- Powered by an 11 HP Honda GX340 engine. Engine kits are available factory installed on 5-foot truss sections for reduced set up time at the job site

- Winch options include manual or self-propelled models. Self-propelled models come completely assembled and mounted on a 2.5-foot section of screed

- Crowns/Inverts may be ordered separately

| Recommended Slump | 3 in | 76 mm |

| Max Concrete Depth | 8 in | 203 mm |

| Max Screed Width | 65 ft | 19.8 m |

| description | Steel truss with eccentric shaft vibrator | |

| Weight | 57 lb | 26 kg |

| description | Steel truss with eccentric shaft vibrator | |

| Weight | 95 lb | 43 kg |

| description | Steel truss with eccentric shaft vibrator | |

| Weight | 136 lb | 62 kg |

The WSHE/MSHE Series Vibratory Truss Screed from Multiquip is a premier solution for concrete contractors seeking exceptional surface flatness, speed, and power for large-scale slabs, bridgework, highways, and industrial flooring. Renowned for robust construction, modular versatility, and superior vibration, this screed system delivers high-quality results for commercial and civil projects across North America and beyond.

WSHE/MSHE Series: Professional Overview

Engineered for both versatility and precision, the WSHE and MSHE series are designed to handle pours ranging from residential flatwork to massive bridge decks. The key to their performance lies in a rugged truss frame built from durable Schedule 80 steel, combined with an innovative eccentric shaft that creates 8,000 vibration cycle nodes per minute—ensuring reliable concrete consolidation and the highest degree of surface leveling. These screeds far surpass traditional hand screeding in both speed and flatness, making them the choice for rapid, extended pours where productivity and finish quality are paramount.

Core Specifications & Technical Features

| Feature | WSHE/MSHE Series Specification |

|---|---|

| Vibration Speed | 8,000 vibrations/minute (nodes) |

| Max Screed Width | 65 feet (19.8 meters), modular |

| Recommended Slump | 3 inches min. (76 mm) |

| Max Concrete Depth | 8 inches (203 mm) |

| Truss Construction | Schedule 80 steel, 16 TPI threads |

| Engine Options | Gas-powered, Honda or similar |

| Blades | 10-gauge galvanized steel |

| Grade Control | 16 TPI (threads per inch) system |

| Setup/Portability | Sectional, bolt-together segments |

| Safety | Engine safety shut-offs, guards |

The truss’s modular design allows any configuration up to 65 feet, while the heavy-duty eccentric shaft delivers deep, uniform vibration for full concrete consolidation.

Key WSHE/MSHE Series Advantages

-

Superior Leveling & Consolidation: 8,000 vibration nodes per minute from eccentric shaft create deep agitation and speed finishing, reducing voids and cold joints.

-

Heavy-Duty Steel Truss: Schedule 80 top pipe and thick, hot-dip galvanized truss members resist flexing, corrosion, and bending under load—outlasting lighter aluminum competitors.

-

Extended Reach: Modular configuration can be built from 10 to 65 feet, making the system suitable for everything from driveways to massive warehouse or infrastructure pours.

-

Flexible Engine Selection: Proven Honda or equivalent engines, matched to site conditions, power long runs for rapid placement without bogging or uneven vibration.

-

Fine Grade Control: Integrated fine-thread (16 TPI) top pipes give operators precision grade control across the full truss length, allowing for easy dialing-in of crown, invert, or level surfaces.

-

Easy Transport & Setup: Individual truss sections bolt together quickly, with lift handles and safety covers facilitating safe deployment and crew handling.

-

Low Upkeep: Oil-lubricated vibration bearings, sturdy guards, and tool-free blade changes minimize downtime on busy jobsites.

Real-World Applications

-

Bridge Decks and Highways: Achieves the flatness tolerances and consolidation required for DOT, municipal, or infrastructure projects.

-

Commercial & Industrial Slabs: Warehouses, distribution centers, retail floors, tilt-ups, and post-tensioned slabs.

-

Large Parking Lots/Paving: Reduces labor and boosts yields for external flatwork; ideal for pavements needing FF/FL floor spec certification.

-

Municipal Buildings & Plant Work: Consistent leveling across varying layouts, contours, or site restrictions.

Durability, Support, and Accessories

-

Rugged Sections: All mainframe and blade elements are galvanized or powder-coated for site-hardening and corrosion resistance.

-

Grade Adjusters & Fine Threads: Heavy-duty, quick-turn grade adjusters allow tight control of pitch or crowned surfaces during screeding.

-

Blade Options: Multiple blade profiles (including crowns, inversions, or flat) are available for specialty requirements.

-

Full Parts Support: Multiquip’s national distribution network and engineering team provide quick shipping for wear parts, extension kits, and repair advice.

Comparison: WSHE/MSHE vs. Standard Screeds

| Feature | WSHE/MSHE Series | Standard Vibratory Screed |

|---|---|---|

| Max Working Width | 65 ft | 20–40 ft typical |

| Truss Construction | Galvanized Schedule 80 steel | Aluminum, lighter steel |

| Vibration Speed | 8,000 nodes/min | 3,600–5,000 nodes/min |

| Engine Power | 7–11 HP (Honda) | 5–9 HP |

| Fine Thread Control | 16 TPI | 8–12 TPI |

| Modular Setup | Full, to 65ft | Partial up to 40ft |

| Best Uses | Bridge decks, large slabs | Smaller pads, short flatwork |

WSHE/MSHE Series in Practice: User Experiences

Experts praise these series for combining “remarkable flatness” with “big job speed,” emphasizing that once a crew is trained, productivity and surface consistency are dramatically improved for pours over 50 yards and up to multi-hundred yard commercial jobs. Crews report the screed is especially effective when used for straight runs and on projects where tolerance and finish quality are at a premium. The learning curve for raker and operator sync is noted, but teams agree that proficiency yields “cream on top” results and easier post-screed finishing with minimal surface defects.

Why Pros Choose the Multiquip WSHE/MSHE Series

-

Exceptional Productivity: Pour more, faster, and flatter—reducing labor costs and increasing profits on each job.

-

Proven Durability: American-made steel construction and fail-safe design yield years (and even decades) of hard use.

-

Precision Results on any Scale: From driveways to bridges, this system offers consistent, code-compliant results, FF/FL tolerance, and easier finishes.

-

Best-In-Class Support: Multiquip’s track record and service guarantee parts, training, and tech support wherever work takes you.