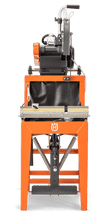

Husqvarna MS610 - 967673503

NOTE: BLADE ON SAWS IN PICTURE ARE NOT INCLUDED : BLADES MUST BE PURCHASED SEPARATELY

This saw proves its value daily on the job, and many of them have been on the job for over 25 years. If you need a production masonry saw you can count on year after year, the reliable Husqvarna MS610 is the saw for the job.

Cutting depth, max: 10 in

Blade diameter, max: 24 in

Output power (As rated by the engine/motor manufacturer): 7.5 hp

Technical Specifications

The Husqvarna MS610 Saw is a high-performance masonry saw renowned for its precise cutting capabilities, exceptional durability, and ergonomic design, making it a top choice among professionals for demanding block, brick, and paver work. Built for tough production environments, this saw offers superior efficiency, reliability, and ease of maintenance, helping contractors tackle large-scale jobs with confidence and speed.

Product Overview

The Husqvarna MS610 saw is engineered for heavy-duty masonry tasks, excelling at cutting blocks, bricks, and pavers quickly and accurately. Its robust build and powerful Baldor continuous duty dual capacitor motor reduce cutting time and improve productivity, while the saw’s replaceable rails and advanced alignment features keep operation smooth and hassle-free. Available with 14”, 20”, and 24” blade guards, it can tackle everything from small detail work to full blocks in a single pass, making it one of the most versatile and valued masonry saws in the industry.

Key Features

-

Blade Capacity and Depth: Models accommodate blades from 14" to 24", supporting max cutting depths of 5", 8", and 10", respectively. The large blade diameter means deep cuts and fewer passes—ideal for 8" x 8" x 16" blocks in one go with a 20" blade.

-

High-Torque Baldor Motor: Equipped with continuous-duty dual capacitor motors (5 HP or 7.5 HP), the MS610 maximizes horsepower for rapid, efficient cutting and reliable power delivery, even during extended use.

-

Ergonomic & Precise Handling: Parallel blade guard, steel handle with molded grip, and Sta-level blade guard maintain alignment and operator comfort for steady, accurate cuts every time.

-

Low Vibration Design: Engine mounting system and sealed bearings minimize vibration and operator fatigue, enabling longer sessions with improved cut accuracy.

-

Robust Water Management: An advanced water spray splash guard and containment system keep slurry controlled and work areas clean. The brass nozzles resist clogging and provide consistent, effective blade cooling.

-

Easier Maintenance: Only two pivot points—sealed and lubricated for life—mean less downtime, with replaceable rails for fast, accurate cart alignment.

-

Flexible Height Control: Cutting head adjustment via crank or foot pedal lets users fine-tune depth for precise work, handling a range of material thicknesses easily.

-

Transportability: Integrated forklift brackets facilitate easy movement across job sites, boosting efficiency and safety during setup and takedown.

Performance and Reliability

The Husqvarna MS610’s advanced engineering delivers smooth, vibration-free operation and accurate repeatable cuts, even in dense materials. With continuous-duty motors, sealed bearings, and parallel guides, it excels on jobs where consistency and speed are critical. The saw’s robust water system protects the blade and supports dust control, keeping both the operator and work environment safe and clean.

Typical Applications

-

Cutting concrete blocks with precision for residential or commercial masonry.

-

Slicing bricks and pavers for landscaping, walls, patios, and walkways.

-

Handling large-format materials and structural units with maximum cut depth for tight construction tolerances.

-

Supporting production environments where reliability and speed are essential.

Maintenance Guidelines

Regular maintenance is key to maximizing the lifespan and performance of the Husqvarna MS610 Saw:

-

Blade Guard Checks: Inspect for damage, ensure the guard is secure and undamaged for safe operation.

-

Rail and Cart Alignment: Replace rails as needed to ensure smooth cutting head movement and accurate alignment.

-

Inspect Hoses and Clamps: Regularly check the water supply hoses and clamps for damage or leaks.

-

Clean Water System: Keep water spray nozzles free of clogs and flush containment systems to prevent slurry buildup.

-

Sealed Bearings: No greasing required, but inspect periodically for signs of wear or damage.

-

Height Adjustment Mechanisms: Maintain crank control and foot pedal for smooth operation and to prevent drift in cut depth.

Operator Safety

-

Always use PPE including goggles, gloves, hearing protection, and steel-toed boots during cutting operations.

-

Confirm all guards and alignment systems are in place before use.

-

Use water system for dust control to protect respiratory health.

-

Follow lockout/tagout protocols and ensure the area is clear of obstructions before moving or servicing the saw.

Frequently Asked Questions

Q: What blade sizes can the MS610 Saw accept?

A: 14", 20", and 24" blades, with cutting depths up to 10” depending on the model.

Q: Is the saw portable?

A: Yes. Forklift brackets and manageable weight allow for easy transport and repositioning on any job site.

Q: What maintenance does the saw require?

A: Sealed bearings need no greasing; periodic checks of blades, guards, rails, and water systems are recommended.

Q: How does the water system work?

A: An advanced, clog-resistant brass nozzle system keeps blades cool and slurry contained for a clean work area with less maintenance.

Conclusion

The Husqvarna MS610 Saw provides unparalleled value and reliability for professionals in the masonry and construction industries. Its robust design, flexible blade options, high-performance motor, and superior water management system are complemented by ergonomic controls and low-maintenance engineering. For block, brick, and paver cutting tasks, the MS610 stands out as a durable, accurate, and easy-to-use saw that supports top productivity while maintaining safe and clean job sites.